Grade steel, also known as tool steel, is used for the manufacture of tools, gauge components, fixtures and other machine and equipment components. E-Invest offers tool steels characterized by high hardness, low deformability and resistance to high temperatures and overheating. This is a high-quality steel from which metallurgical products are manufactured. In our offer you will find quality steel at excellent, attractive prices. These include:

- Alloy tool steel for cold work, in the form of round bars, flat bars, square bars and plates;

- Alloy tool steel for hot work, in the form of round bars;

- Carbon tool steel – shallow hardening, in the form of round bars, flat bars and sheets;

- High speed steel, in the form of round bars, flat bars and square bars;

- Steel for carburizing, in the form of round bars;

- Nitriding steel, in the form of round bars;

- Structural alloy steel for refining, in the form of round bars.

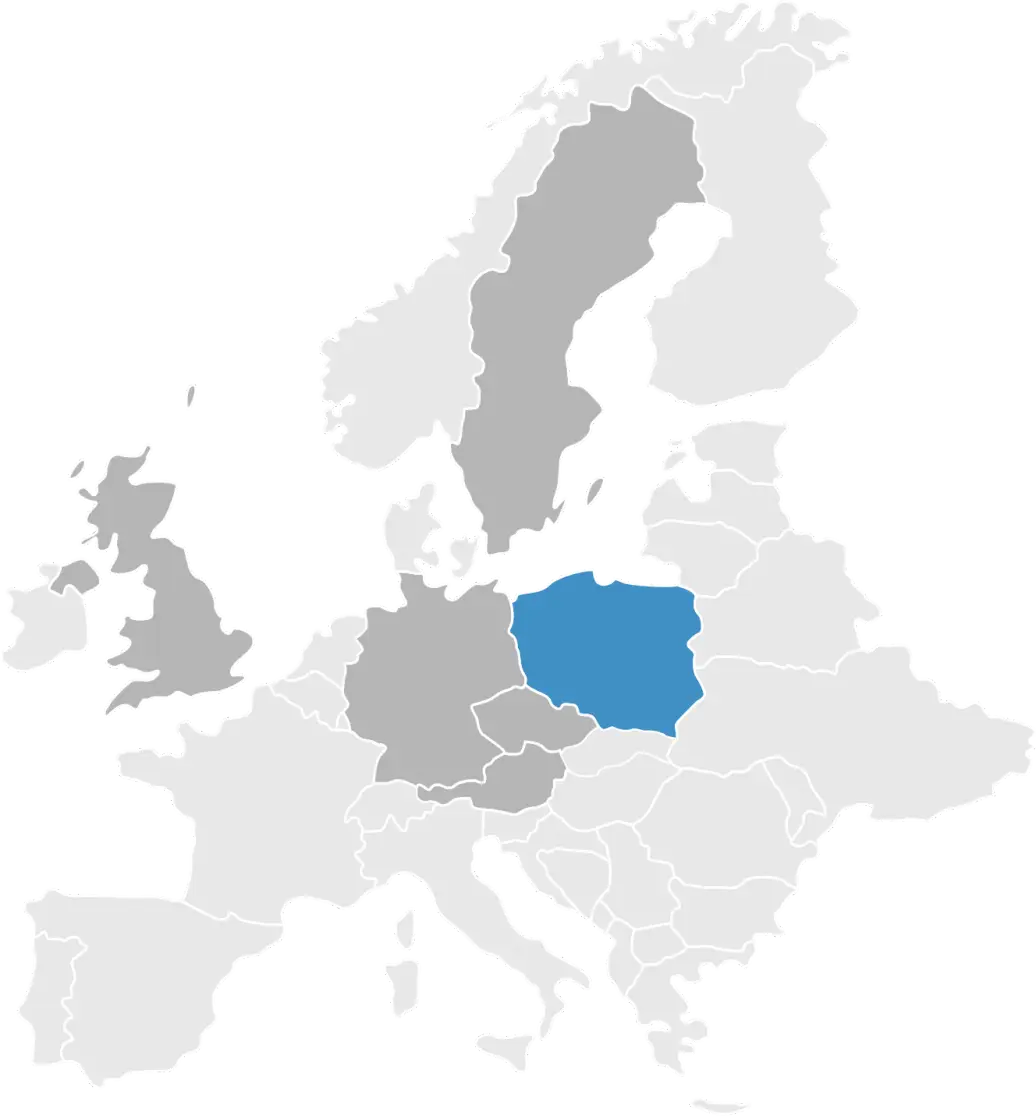

COLD WORKING ALLOY TOOL STEEL

Tool steel alloy steel for cold working PN-86/H-85023 (extract) in grades: NC10, NC11, NC11LV, NZ3, NWV, N8-11E

- round bars

- flat bars

- square bars

- sheets

UPON REQUEST, WE SUPPLY MATERIAL IN OTHER GRADES

APPLICATIONS:

NC6 – taps, dies, reamers, mills, machine bits; gauges; dies; and punches.

NC10 – punches; draw rings; knives; gauges; punches; forging rolls.

NC11 – drawing dies; draw rings; punches; threading dies; knives; dies; extrusion blunts.

NC11LV – drafters; cutters; cutters; reamers; punches; cutting tools for paper, marble and plastics .

NMV – gauges; measuring tools; long taps and dies; reamers; punches; disc knives and discs; cutters; punches.

NZ3 – punches; chisels; dies; woodworking tools; punches; graders.

NW1 – knives for wood, paper, tobacco, rubber; drills; spirals; saws and saws; stepmills.

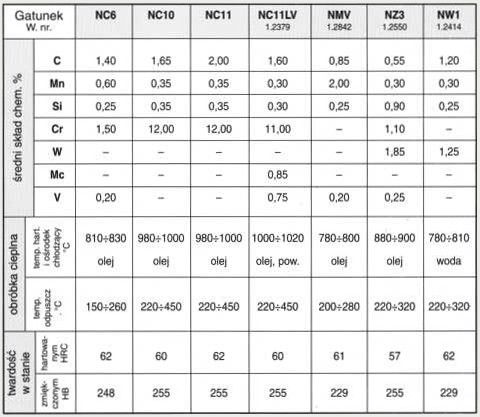

HOT WORK ALLOY TOOL STEEL

PN-86/H-85021 (extract) in grades: WCL, WCLV, WNL, WWN1, WWS-1, WWV

- round bars

ON REQUEST WE DELIVER ON MATERIAL IN OTHER GRADES

APPLICATIONS:

WCL – die casting molds under pressure; die inserts, for highly loaded press parts

WCLV – die inserts, dies and punches for extrusion, thrust rolls

WNL – forging dies, anvils, punches

WWN1 – dies, pressure molds, hot drawing dies

WWS1 – pressure molds, punches, dies, hot drawing dies

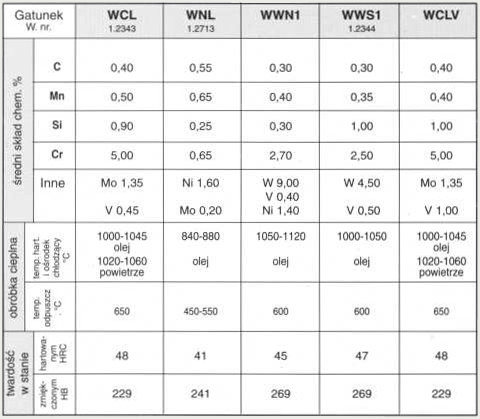

COAL TOOL STEEL – shallow hardening

PN-86/H-85023 (extract) in grade: N9E

- round bars

- flat bars

- sheets

APPLICATIONS:

N9E – punches; taps; dies; woodworking and metal-chipping tools.

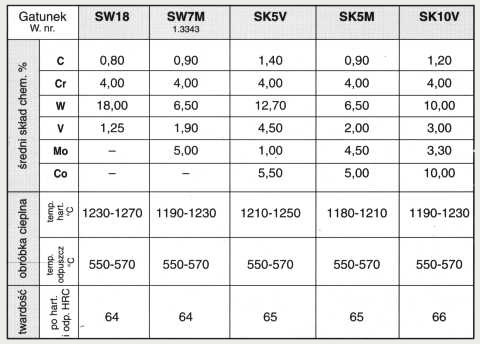

HIGH SPEED STEEL

PN-86/H-85022 (extract) in grades: SW7M, SW18, SK5, SK5V, SK5M, SK10V

- round bars

- flat bars

- square bars

APPLICATIONS:

SW18 – cutters, drills, saw blades, knives

SW7M – spiral drills, tools for thread cutting and gear machining, reamers, cutters

SK5V – lathe knives and chisels, cutting wheels, tools for automatic machines

SK5M – planer knives, lathe knives, cutters, drills

SK10V – high-performance mills, turning and milling cutters

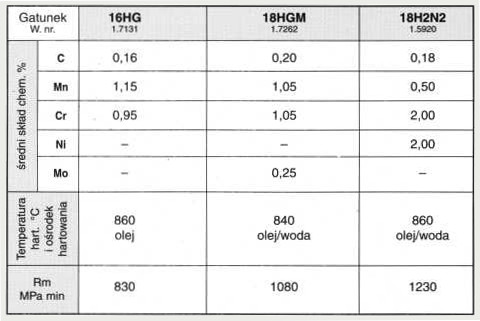

STEEL FOR CARBURIZING

PN-89/H-84030-02 (extract) in grades: 16HG, 18HGM, 18H2N2

- round bars

ON REQUEST WE SUPPLY MATERIAL IN OTHER GRADES

APPLICATIONS:

16HG – camshafts, gears, pins, etc. details subject to abrasion.

18HGM – for parts with high core strength, such as gears and shafts subject to high pressures and variable loads.

18H2N2 – for parts with large dimensions, very high core strength and ductility, such as gears, gears operating at high speeds, sleeve wheels, pins.

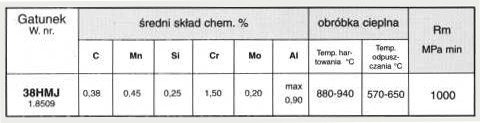

STEEL FOR NITRIDING

PN-89/H-84030-03 (extract) in grade: 38HMJ

- round bars

APPLICATIONS:

38HMJ – for parts with the highest strength properties, with a surface hardness of about 900 HV.

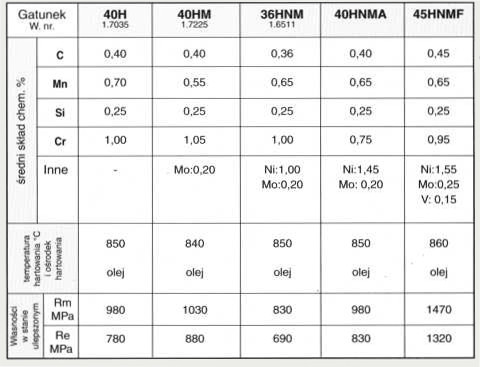

STRUCTURAL ALLOY STEEL FOR UPGRADING

PN-89/H-84030/04 (extract) in grades: 15-45HN, 34-36 HNM, 40H, 40HM, 36HNN, 40HNMA, 45HNMF

- round bars

ON REQUEST WE SUPPLY MATERIAL IN OTHER GRADES

APPLICATIONS:

40H – for heavily loaded shafts, bushings, axles, gears

40HM – for gears, shafts, rotors, parts for equipment in the oil industry.

30HNM – for parts with cross sections up to 100 mm, with high strength and good ductility

40HNMA – for parts of turbines with a cross section up to 100 mm, working at temperatures up to 450oC

45HNMF – for important machine parts of the highest strength with cross sections up to 180 mm.