Steel gratings can be used to make universal standard and non-standard spiral staircases. In such cases, stair gratings are used as entrances to tank decks or deck gratings in industrial halls. Spiral stairs are built in escape staircases, used as entrances to the attic or basement.

Spiral stairs are used as exterior or interior stairs. Their advantage is their modular design and the fact that they occupy a small space compared to traditional wooden stairs. Spiral staircases are easy to install and there is a possibility of angular adjustment to existing elements with them. They have a low weight relative to their height, and the price of spiral stairs is low compared to traditional stairs.

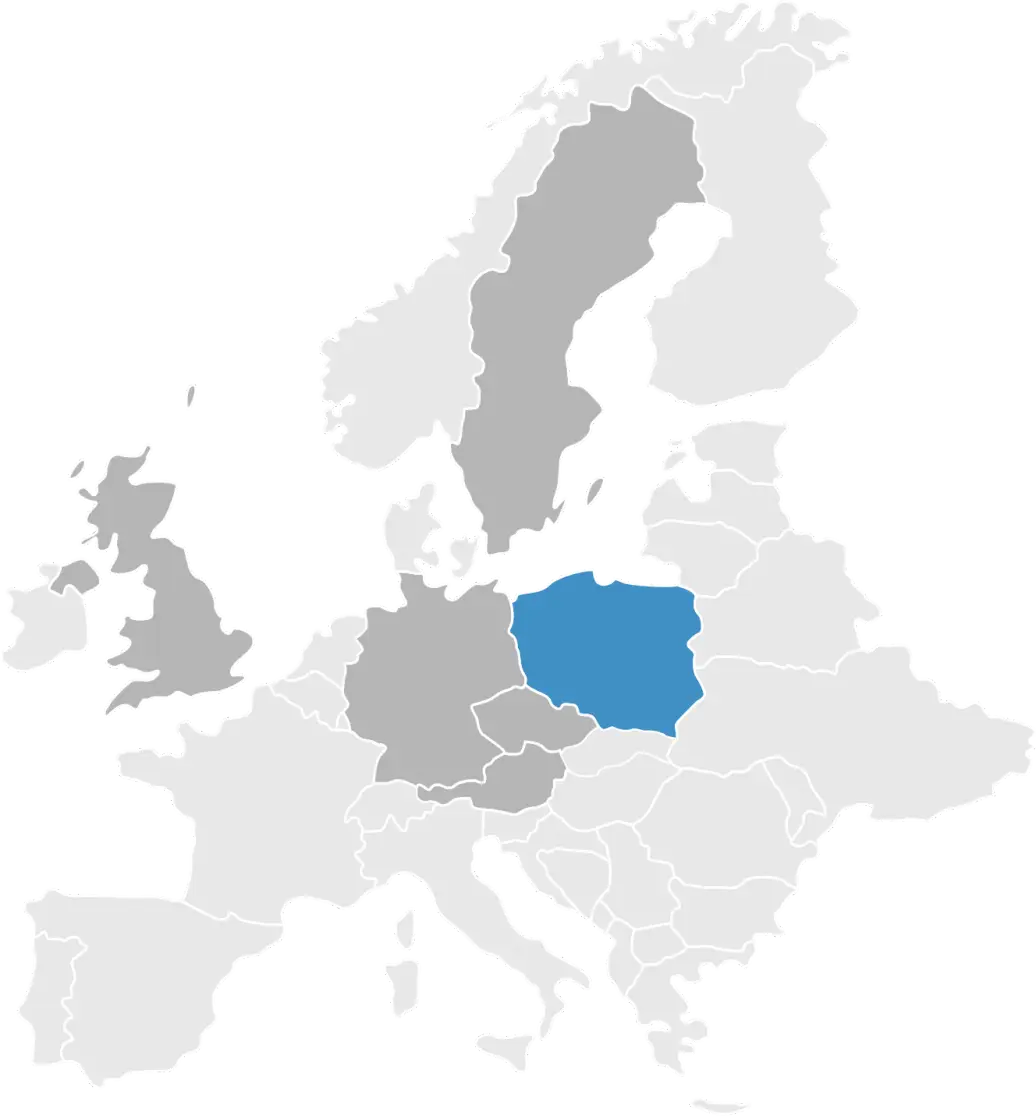

E-Invest offers spiral stairs that meet all the requirements of building regulations and Polish standards. The steps of spiral stairs should be installed in such a way as to maintain the recommended distances between them and the edges of the profile ends and the posts passing through the platforms.

The figures below show the recommended distances that should be maintained during the design and installation of gratings-from the edges of the terminating profiles, from the posts passing through the platforms, from pipes, walls and hall enclosures. They also show what distances should be kept between gratings when they are laid out. At the design stage, the distances between gratings should be taken as zero. It should also be remembered that gratings are made with negative tolerances. Maintaining the recommended dimensions will ensure that the gratings are properly designed and arranged on the platforms.

Spiral staircases are made in a way that allows self-assembly. Since our stairs meet all the requirements of building regulations and PN-80/M.-49060, it is necessary to observe the following guidelines:

(a) External diameter of the stairs

D=from 2000[mm]

b) Step height of stairs

h=from 175 to 200[mm]

c) Number of stair treads per full turn (360°)

n=from 16 to 19 (depending on the diameter D)

d) The staircase must be able to anchor the support pipe at a minimum of every 3-8 mb. height.